Our Values

Danco Medical is well known for its ability to maintain quality requirements, to meet short deadlines, and to retain detailed records.

More About UsOur Services

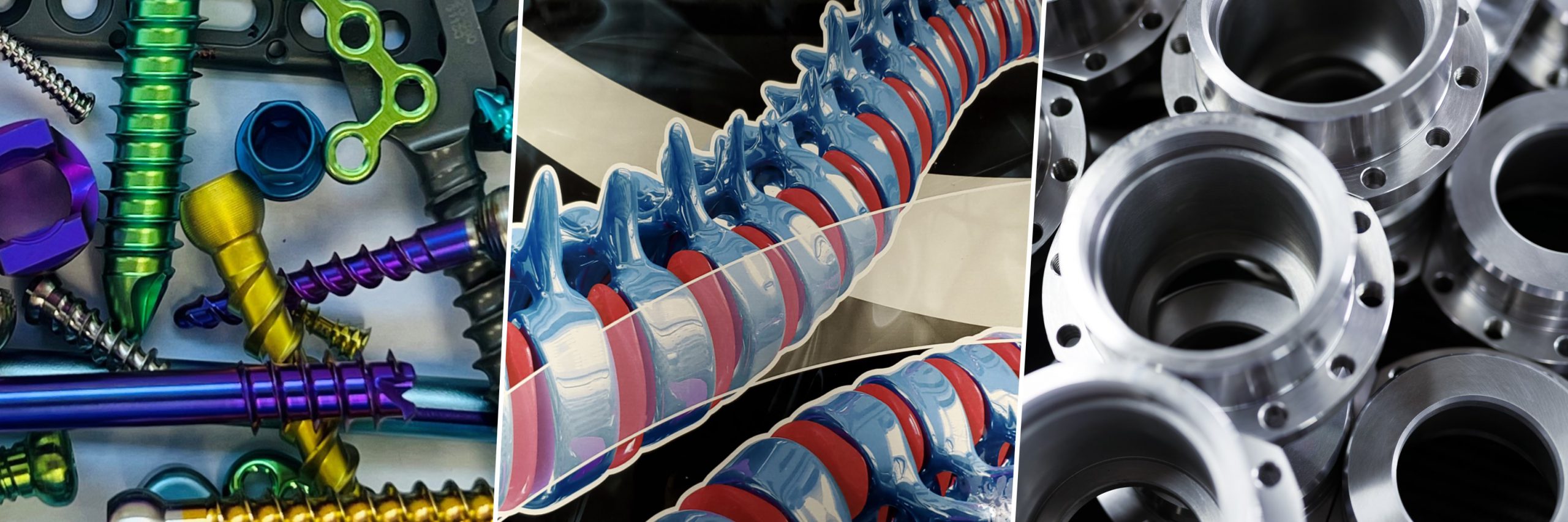

Providing titanium and aluminum anodizing of machined parts, implants, instruments, and devices, as well as electropolishing, passivation, and Low Friction Chrome Coating.

MoreOur Certifications

Danco Medical is ISO 13485 certified, Nadcap certified, ITAR compliant, and RoHS REACH compliant.

More