Titanium Anodizing

The Finish of Choice for Orthopedic Implants. Titanium anodizing provides products with improved properties compared to those in a raw or “unfinished” state. The two most common types of treatment are Type 2 Anodizing and Color Anodizing. Color Anodizing and Type 2 Anodizing can be combined through a masking process to achieve the benefits of... Continue reading→

EP, Passivate, and Epoxy

Electropolishing is an electrochemical finishing process that removes a thin layer of material from a metal part. The most common materials are 300-400 series stainless steel. The material is removed by a controlled cycle time and amps that pass through the surface of a part resulting in a bright shiny finish. This improves corrosion resistance... Continue reading→

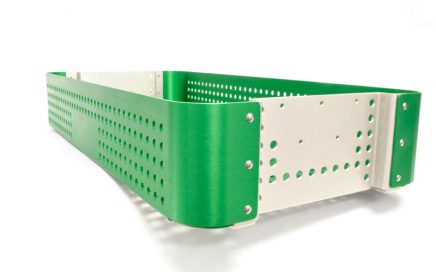

Aluminum Anodizing

The most common and cost-effective anodizing process. Provides excellent abrasion and corrosion resistance. Except for die castings, these coatings are easily dyed a wide range of colors. Thickness typically is (.0003-.0007), MIL-PRF-8625 (formerly MIL-A-8625), Type II, Class 1 (clear) or Class 2 (color). See attachment for Danco Medical standard color gages. Danco Medical can also... Continue reading→

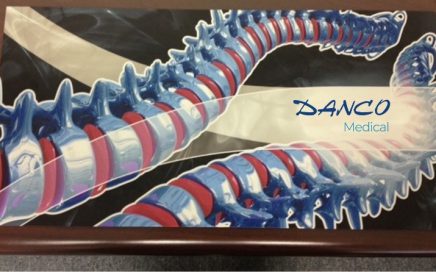

Deep Image Graphics

Danco Medical’s Deep Image is an industry leading offering that utilizes Danco’s aluminum anodizing process. Deep Image is applied to aluminum components and has the advantage of its durability along with being cost competitive when compared to multi-colored screen print applications. Deep Image offers companies the ability to stand out from competitors. For more information... Continue reading→

Low Friction Chrome

This process follows the industry standard specification AMS2460. Chrome achieves a true build up of .0001”-.0003”. Caution must be made in cases of ID holes, slots, recesses and corners. Reach out to your Danco Medical trusted source for questions. Reduces friction on mating parts Improves corrosion resistance Reduces spotting, rusting, peeling, and other degradation caused... Continue reading→

Laser Etching

Danco Medical’s laser etching offers the ability to stand out against the competition. We are capable of etching an array of materials such as aluminum, stainless steel, plastics, titanium, and cobalt chrome. Please contact Danco’s sales team for any questions.

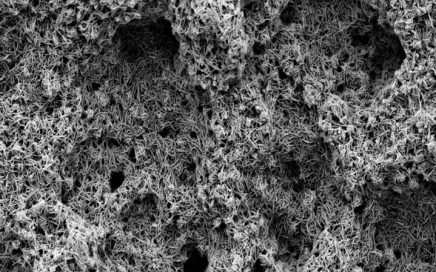

HAnano Surface

In 2022 Promimic AB and Danco Medical – a Lincotek Group Company – formed a joint venture focused on the processing of HAnano Surface for medical implants in the US market. This company is called Nano Processing, Inc. (NPI). NPI is built around Promimic’s core technology, HAnano Surface. The HAnano Surface is a 20 nanometer thin layer of hydroxyapatite (HA)... Continue reading→