Titanium Anodizing

The Finish of Choice for Orthopedic Implants.

The Finish of Choice for Orthopedic Implants.

Titanium anodizing provides products with improved properties compared to those in a raw or “unfinished” state. The two most common types of treatment are Type 2 Anodizing and Color Anodizing. Color Anodizing and Type 2 Anodizing can be combined through a masking process to achieve the benefits of both color for identification and Type 2.

Color Titanium Anodizing

There are no pigments or dyes involved. Colors are generated by a transparent oxide film grown on the metal surface. The colors develop when part of the light striking the surface reflects and part passes through the film to reflect off the metal below. When the delayed light reappears and combines with the surface light waves, they may either reinforce or cancel. This generates a specific color. The thickness of the oxide film dictates the color. In nature these colors can be found in the eddies of an oily wet street and in the iridescent colors of some insects.

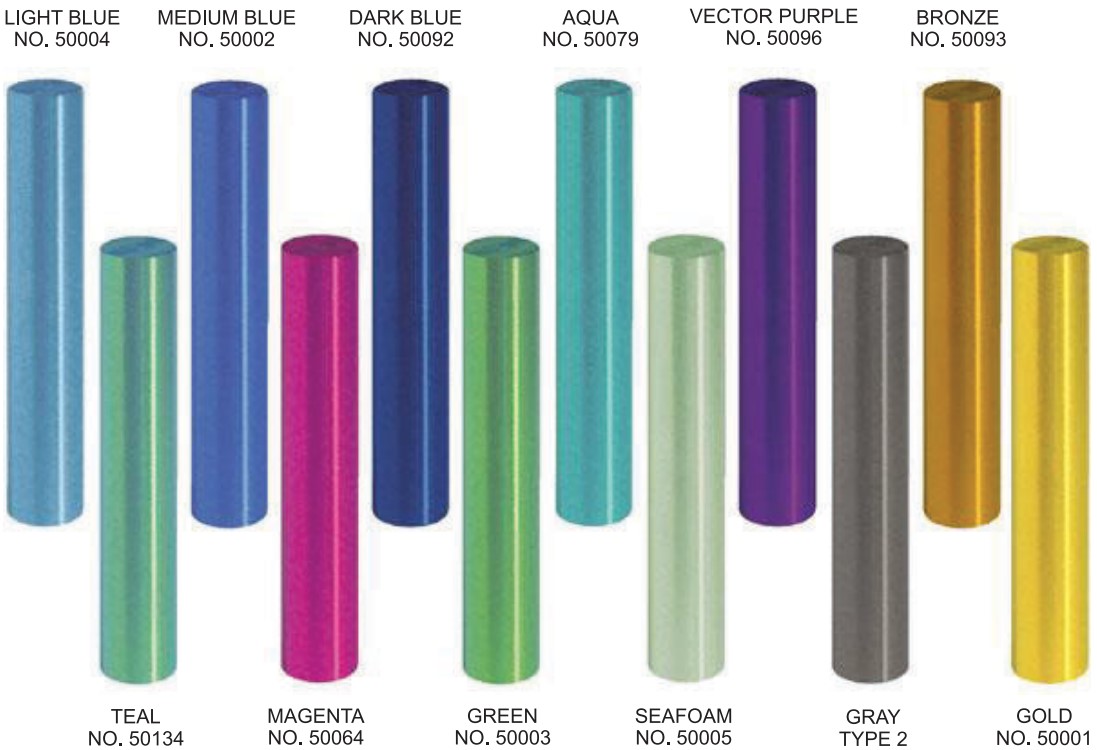

Titanium Anodizing Color Selection Guide

NOTE: Standard colors shown are for reference only and may be affected by the type of monitor used, product surface finish and other factors. Additional colors in spectrum can be achieved as well.

NOTE: Standard colors shown are for reference only and may be affected by the type of monitor used, product surface finish and other factors. Additional colors in spectrum can be achieved as well.

Contact Danco Medical for sample colors and to discuss your needs.

Type 2 Titanium Anodizing - Non-Toxic and Bio-Compatible

Anodic treatment of titanium and titanium alloys for implant products known as “Type 2” anodization is typically performed to AMS 2488. SAE International now has responsibility for this specification and the current revision is dated June 2000. As this process is covered under an Aerospace Material Specification, it was first developed for treatment of parts associated with the air and space industries. The properties most often discussed, increased lubricity, anti-galling, and increased fatigue strength were not associated with the medical industry. As the advantages of anodizing titanium became apparent in orthopedic implants, the popularity and acceptance of this coating grew. In addition, toxicity and biocompatibility were not an issue. The anodization process accelerates the formation of an oxide coating under controlled conditions to provide the desired result.

Advantages of Type 2 Titanium Anodizing

- Produces anti-galling and wear resistant properties at the surface.

- No introduction of hydrogen or hydrogen embrittlement.

- Increase fatigue strength up to 20% due to the homogeneous surface treatment.

- Coating forms as a penetrating layer rather than growth or “build-up” at the surface, which results in no dimensional change.

- Process may be successfully utilized on both CP and most commercial alloys of titanium.

- Titanium anodize is semi-conductive which allows re-anodization without need for stripping the original coating. Bare or machined areas will “heal” over and be indistinguishable from the original.

- Improvement to surface finish of greater than 50% is attained without special vibratory or burnishing methods.

- As the coating has increased lubricity, in moving parts there are improvements to surface finish, reduction in erosion and abrasion, and the prevention of wear by fretting.

Lined Spinal Rods

Anodized lines are preferred over laser etched lines due to improved integrity of the titanium rod. Contact Danco Medical Sales to discuss your color spectrum requirements.